- Your cart is empty Browse Shop

Case Details

Case Study : MEASUREMENT SOLUTIONS FOR NEW ENERGY BATTERY

Sector: Automotive Sector

Category: PMT

Download Case Details

Download a detailed report on this case

MEASUREMENT SOLUTIONS FOR NEW ENERGY BATTERY

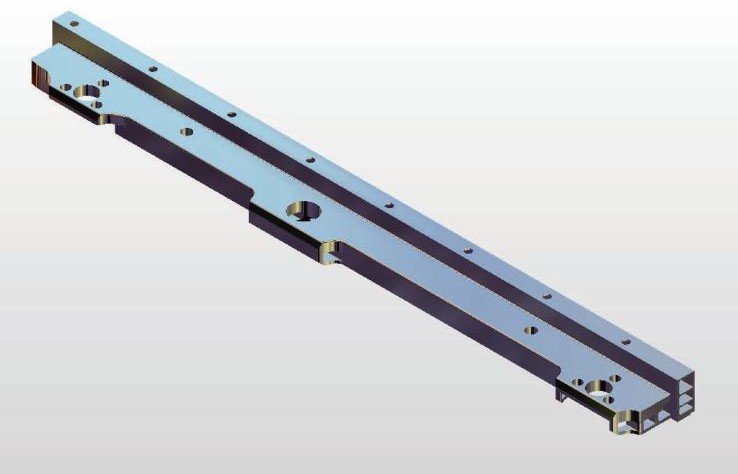

Battery case has been seen as a core component of new energy vehicle. So it is vital to balance its weight with structural intensity and safety. During design and production of shells for battery cases, we need to use different parts for welding and usually these parts have various sizes. Therefore, whether the size of a single part meets the standard is the primary guarantee in the quality control process. Battery case comes with IP67 water resistance, which is usually achieved by silicon rubber sealing ring.

Objective:

To measure the flatness of the mounting surface of the upper and lower shell of the battery box.

Challenges in the Project

- In actual assembly, there are strict requirements on the amount of compression of the silicon rubber ring, which will be directly affected by the flatness of the mounting surface of the upper and lower shell of the battery box.

- if the flatness is not up to the standard, it will lead to the overpressure or air pressure of the ring during installation, resulting in the failure of the silicon rubber ring and potential risks.

- The traditional tools such as feeler gauge and dial gauge can not achieve good results as they have low efficiency and accuracy.

PMT ALPHA ARM can measure the point position of parts and transform the data into the reference target. After processing, the theoretical data can be compared directly, and then we can easily see how the sizes change

The measurement results are shown as below: