- Your cart is empty Browse Shop

Case Details

Case Study : EPlus-3D Case Studies

Sector: Automotive Sector

Category: EPlus

Download Case Details

Download a detailed report on this case

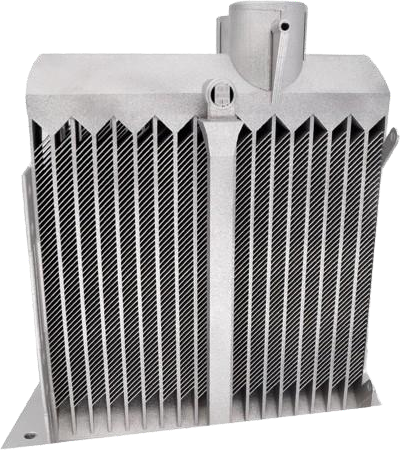

Metal 3D Printing: Heat Exchanger

Benefits of 3D Printed Heat Exchanger

Access to more complex design:

In heat exchanger design, this advantage enables thinner walls (200 microns) and complex channels, increasing surface area and improving heat transfer performance.

Lightweight and Generative Design:

Most heat exchangers have complex designs that complicate installation, while 3D printing allows for lighter, more compact equipment with equal or better performance.

Stability and quality:

A 3D printed heat exchanger is made in a single operation, eliminating seams and reducing leakage risk. This streamlined process lowers variability and enhances overall quality.

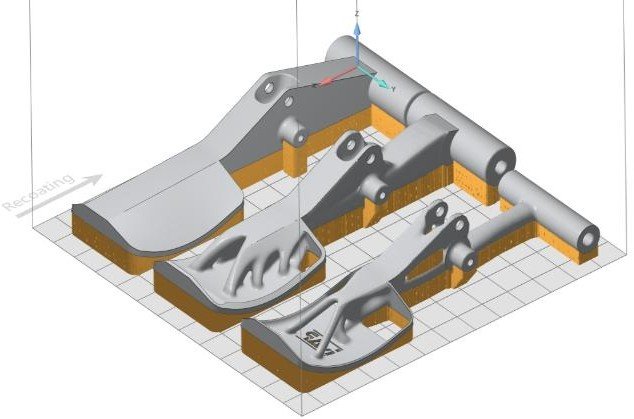

Optimizing Accelerator Pedal Design for Lightweight

The accelerator pedal was designed for lightweight construction and material efficiency, reducing costs and providing a competitive edge. Siemens Digital Industrial Solutions

showcased its state-of-the-art design capabilities by using the Generative Design Module in Solid Edge for an automotive racing car accelerator pedal.

As demonstrated by Siemens, the benefits of designing parts for lightweight construction include:

- Reduced number of components from 4 to 1

- Eliminated sheet metal manufacturing processes

- Eliminated welding process

- Changed from steel to aluminium

- Reduced weight by 62%

- Improved performance

- Reduced environmental impacts

- Saves precious material sources