- Your cart is empty Browse Shop

Case Details

Case Study : Metal 3D Printing Achieves Lightweight Manufacturing in Aerospace Industry

Sector: 3D Printing

Category: Rapid Prototyping

Download Case Details

Download a detailed report on this case

O’Fallon Casting Overview

O’Fallon Casting is a leading manufacturer of investment cast components serving industries including; aerospace, defense and energy. With a strong focus on precision, quality, and innovation, the company continuously seeks advanced manufacturing and inspection technologies to reduce time-to-market for complex components.

Challenge

O’Fallon Casting faced a recurring challenge in its prototype development workflow:

- Conventional Inspection Methods Were Slow: Traditional touch-trigger CMM (Coordinate Measuring Machine) inspections were time-consuming, especially when validating early-stage foam patterns created through SLA (Stereolithography) or SLS (Selective Laser Sintering)

- Delayed Feedback Loops: Long inspection turnaround times limited the team’s ability to respond quickly to design changes or quality concerns, hampering agility in early-stage product development

- Limited Visualization: Tabular CMM data lacked intuitive visualization, making it harder to communicate deviations and quality issues to both internal stakeholders and customers

Solution Deployment

To overcome these inefficiencies, O’Fallon Casting, deployed a high-precision, laser scanning-based metrology solution, featuring:

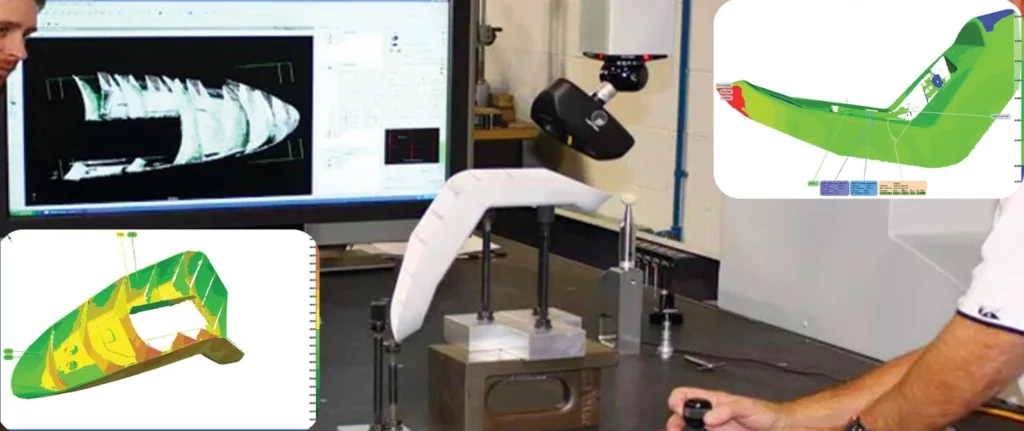

1. Laser Scanner-Equipped CMM

A state-of-the-art laser scanner was integrated with an existing CMM, enabling high-speed, non-contact scanning of intricate foam and cast patterns. The scanner could capture dense point clouds in minutes, drastically reducing cycle times.

2. PolyWorks|Inspector™ Software Integration

PolyWorks|Inspector™, a powerful 3D metrology software that supported the entire inspection workflow:

- SLA/SLS Foam Pattern Scanning: initial pattern was scanned to generate a high-resolution 3D representation

- Data Optimization: overlapping and noisy scan data were automatically filtered out, ensuring clean and efficient datasets

- CAD Comparison: scanned model was aligned and merged with the nominal CAD model to assess dimensional accuracy

- Mesh Generation: a polygonal mesh was created to support detailed feature analysis

- Color Deviation Maps: visual inspection using heat maps provided quick insights into surface deviations, wall thickness, flatness and other critical features

- GD&T Evaluation: tolerances based on ASME standards were checked to ensure conformance of both patterns and final castings

Key Outcomes & Benefits

50% Faster Inspection Cycles

- Average inspection times for foam patterns and cast parts were cut in half, significantly boosting throughput without sacrificing accuracy

Accelerated Rapid Prototyping

- The fast feedback loop enabled by 3D scanning and instant visual reports allowed the design and casting teams to iterate quickly and confidently; crucial for aerospace prototyping where timelines are compressed

High-Fidelity Visual Reporting

- PolyWorks reports with interactive 3D deviation maps improved collaboration between inspection, design, and manufacturing teams

- Customers received more actionable insights, leading to faster approvals and clearer communication on rework or design modifications

Unified Digital Workflow

- By inspecting both molds and final castings within the same software environment, the team ensured process consistency, reduced handover errors, and improved traceability across the part lifecycle

Conclusion

This successful implementation highlights how digital inspection solutions – when properly integrated with manufacturing workflows – can drastically enhance agility, precision and customer responsiveness.

With CMM integration and metrology software (Polyworks), O’Fallon Casting has elevated its prototype inspection capabilities to meet the rigorous demands of modern aerospace manufacturing.