Our Process.

Discover OTS’s streamlined approach: innovative, tailored solutions with cutting-edge technology and expert support to drive your project’s success.

- Home

- Our Process.

Our Process.

Discover OTS’s streamlined approach: innovative, tailored solutions with cutting-edge technology and expert support to drive your project’s success.

- Home

- Our Process.

At Octave Technology Solutions (OTS), we transform visionary concepts into tangible, market-ready innovations through a meticulous, end-to-end product lifecycle. Whether you’re launching a groundbreaking new product or enhancing an existing design, our state-of-the-art capabilities ensure precision, efficiency, and exceptional quality at every stage. Leveraging advanced technology, industry-certified processes, and a team of seasoned experts, OTS guides your project from initial ideation to successful deployment, meeting the highest industry standards and exceeding client expectations.

Step 1. Design

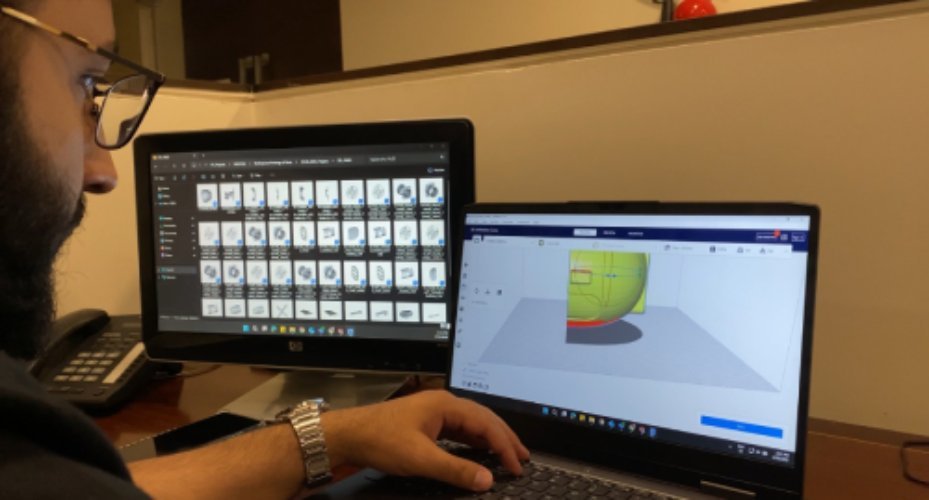

- Utilizing advanced Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE) software, we craft detailed 3D models and simulations. This ensures structural integrity, optimizes material usage, and predicts performance under real-world conditions, reducing costly revisions later in the cycle.

- Our Product Data Management (PDM) and Product Lifecycle Management (PLM) systems provide a centralized platform to track, manage, and share design data across teams. This enhances collaboration, ensures version control, and maintains a comprehensive history of your product’s evolution from concept to completion.

- Reverse Engineering for Upgrading and Reimagining Existing Products Using high-resolution 3D scanning with tools like Shining 3D scanners, we capture intricate details of existing products. This data is converted into actionable CAD models, allowing us to modernize legacy designs, improve functionality, or adapt them for new applications with precision and creativity.

Step 2. Development

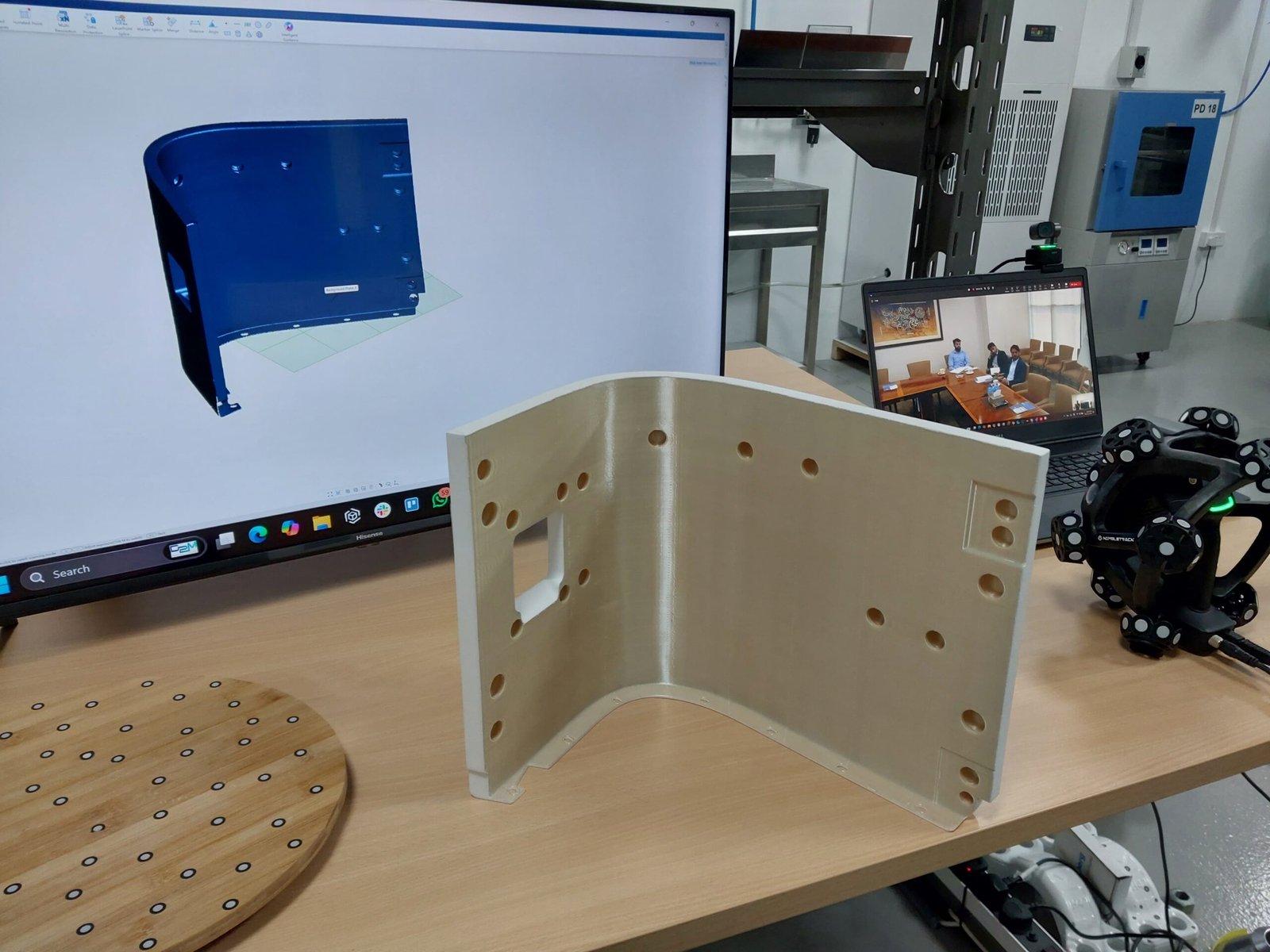

- With versatile 3D printing technologies, we produce initial prototypes quickly and cost-effectively, enabling early-stage testing and design validation across a wide range of materials.

- Leveraging Stratasys polymer 3D printers, we create durable, high-resolution prototypes ideal for functional testing, aesthetic evaluations, and low-volume production runs with materials suited for various industries.

- Using Eplus3D systems, we offer metal additive manufacturing for complex geometries and high-strength components, perfect for aerospace, automotive, and industrial applications requiring robust prototypes.

- Our investment casting services provide high-precision metal parts for early testing, allowing you to evaluate performance and durability before scaling to full production. Short-run production batches ensure flexibility and rapid feedback loops.

Step 3. Manufacturing

- As the region’s first European Union Aviation Safety Agency (EASA)-certified additive manufacturing facility, we guarantee aerospace-grade quality, regulatory compliance, and cutting-edge production capabilities for safety-critical components.

- Our ISO 9001 certified Metal Injection Molding (MIM) process delivers high-volume production of intricate, high-strength metal parts with excellent surface finish and dimensional accuracy, ideal for consumer electronics, medical devices, and automotive sectors.

- Custom Fabrication and Post-Processing for Robust and Market-Ready Parts Through CNC machining, conventional fabrication, and advanced post-processing techniques, we refine parts to meet exact specifications. This includes heat treatment, surface finishing, and assembly, ensuring your products are durable, aesthetically pleasing, and ready for market deployment.

Step 4. Quality Control (QC)

- We utilize state-of-the-art metrology tools to measure and analyze dimensional accuracy, tolerances, and material properties, providing detailed reports to certify product quality.

- Employing Shining 3D scanners, we conduct non-contact inspections to detect deviations and ensure consistency across production batches, enhancing quality at every stage.

- Our PMT Portable Coordinate Measuring Machines (CMMs) allow for on-site verification, enabling real-time quality checks at your facility or ours, ensuring compliance without disrupting your workflow.