Covering the full range of laser SLS/SLM, binder jet 3DP/BJ processes, and full sizes from millimeter to meter.

On the basis of years of 3D printing 1.0 equipment and applications, we have independently mastered 3DP and BJ line scanning high-speed 3D printing 2.0 equipment, materials and processes, which can meet the manufacturing needs of products of different sizes (from millimeter to meter), and independently researched and developed a series of intelligent equipment, such as SLS selective laser sintering, SLM selective laser melting, 3DP sand printing, BJ binder jet metal/ceramic printing and so on. English version of the introduction of industrial 3D printers: Industrial 3D Printers

Industry Applications

Aerospace, ship pumps and valves, automotive and new energy, energy power, industrial machinery, rail transportation, 3C electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical treatment, etc.

Through the “3D casting” technology to provide aerospace users with engine parts, spacecraft structural components, power units and other important parts, can greatly shorten the development cycle of new aerospace products, reduce production costs, ensure the quality of production, and improve the casting yield rate.

Through the “3D casting” technology, we have rapidly delivered parts and structural components for customers in the energy power field and supply chain enterprises. It can help customers realize one-piece molding of large-size, large-plane, complex cavity and other structures, solve the problems of high cost of molding, long cycle, poor consistency, etc., and realize the rapid delivery of small and medium-lot products.

Through the “3D casting” technology, we have delivered cylinders, pumps, housings, impellers, gearboxes and other products to customers in the field of industrial machinery. To help customers realize the small batch of multi-species, complex structure of the product molding, no need to open the mold, shorten the delivery time, reduce costs at the same time to improve the traditional casting process is difficult to achieve, low yield and so on.

Through the “3D casting” technology, we provide new energy vehicle motor shells, lightweight frames, shells, cylinder blocks/cylinder heads, exhaust pipes and other products for domestic and foreign famous automobile brands. We can flexibly meet the customer’s demand for structural and dimensional changes during the R&D stage, improve R&D efficiency, and help the customer to improve efficiency, reduce costs and accelerate the product launch during the new product R&D stage.

With domestic and foreign consumer electronics head manufacturers have layout 3D printing technology in cell phones, watches and other 3C products, such as folding screen cell phone shaft cover, electronic watch case, cell phone frame, bezel and other parts using 3D printing technology manufacturing, 3D printing technology in the mass production of consumer electronics parts and components in the application (3D3C) is accelerating the penetration.

SANDI has pioneered the application of 3D printing in rehabilitation medical treatment (3D medical treatment), obtained China’s first registration certificate for 3D printed customized titanium alloy hearing aids, and established a sales channel for “Taiyin” system hearing aid products. At the same time, we have 3D printed digital dental equipment and material technology, and promote digital dental solutions in dental clinics, including dental implant surgical guides, dental molds, temporary crowns, crowns, veneers and so on;

Industrial 3D printers

Covering the full range of laser SLS/SLM, binder jet 3DP/BJ processes, and full sizes from millimeter to meter.

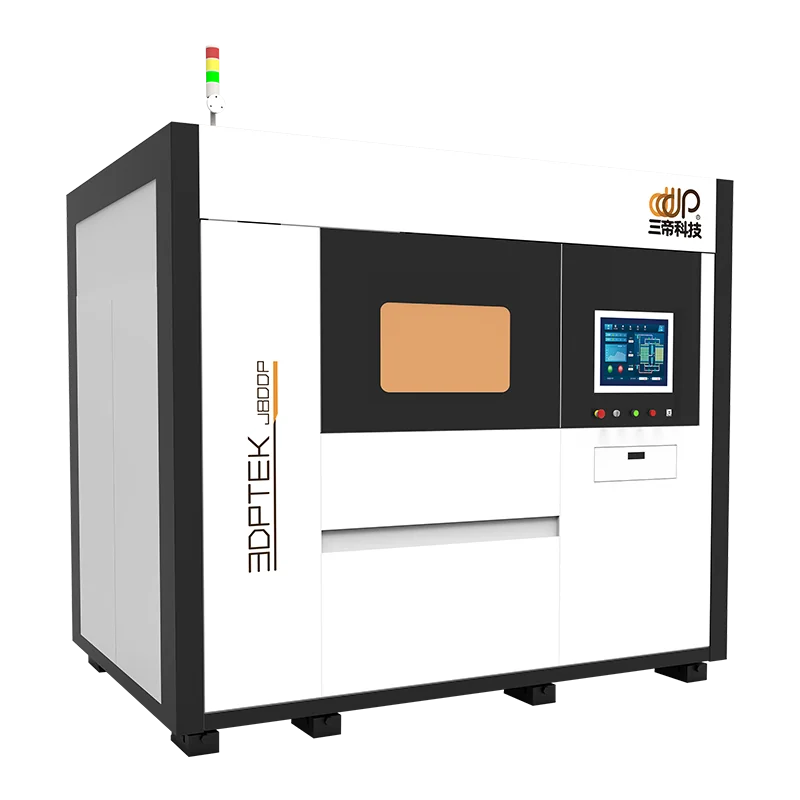

3DPTEK-J400P

3DPTEK-J800P

AFS-M120

AFS-M120X

AFS-M120XT

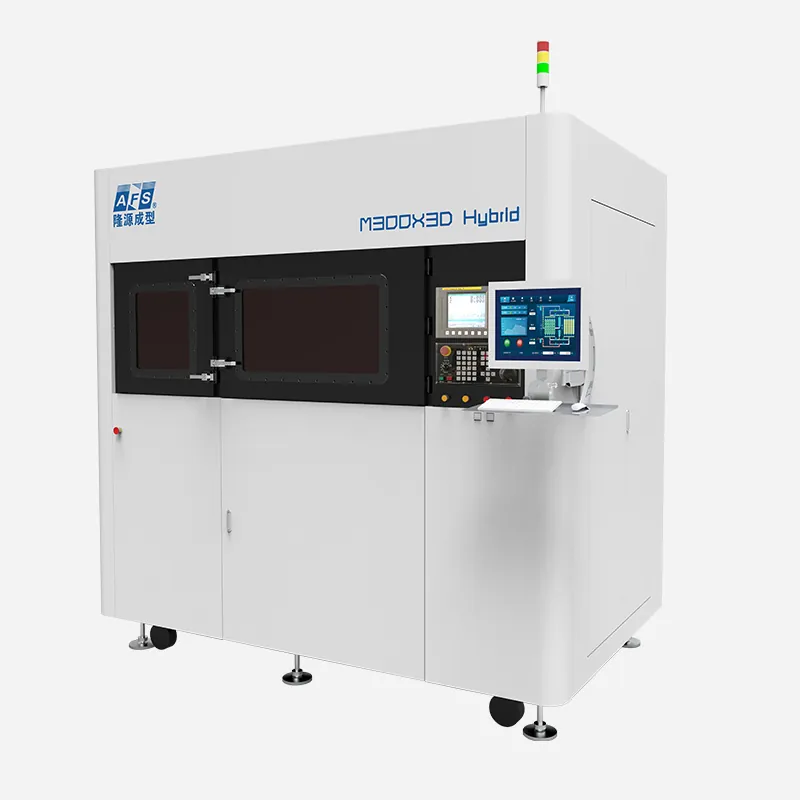

AFS-M300XAS

Need Help in Finding Your 3D Printer?

Tell us about your project and our team of experts will recommend the best solution for you.